Dynamic Seal 302951 High Quality Waterjet Cutting Machines Parts

Short Description:

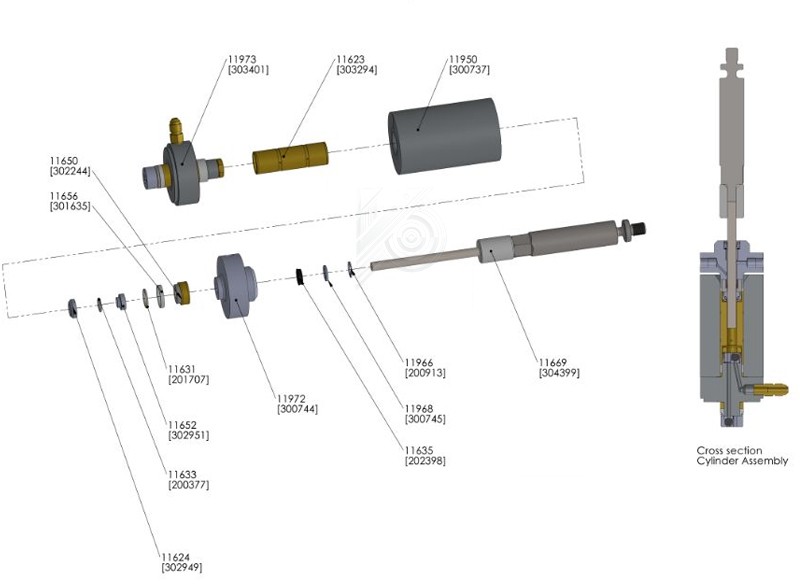

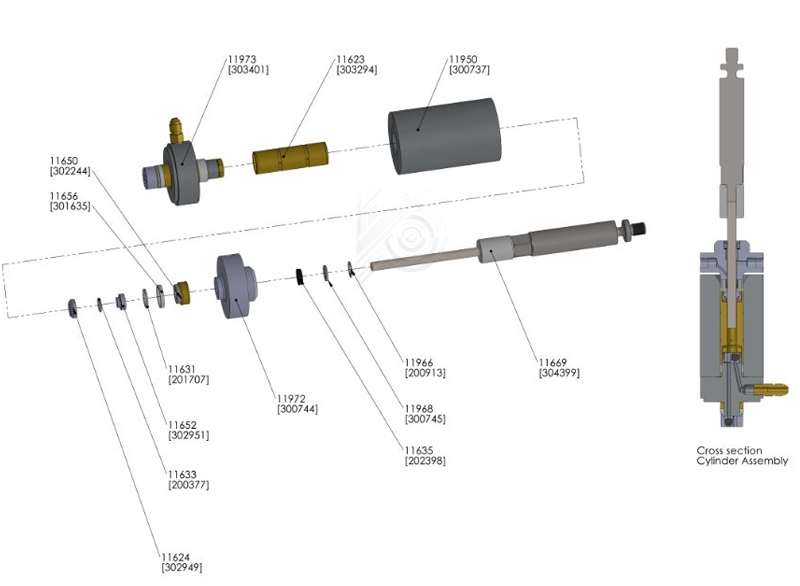

Parts:302951 Dynamic Seal,Omax Waterjet Parts Article number: 11652 Outer Diameter (OD): 0.570 in (14.48 mm) Inner Diameter (ID): 0.311 in (7.90 mm) Cross-Section: Standard dynamic seal profile Material: Gray elastomer (proprietary blend for high-pressure wear resistance) Pressure Rating: Up to 60 000 psi (4 100 bar) Operating Temperature: −20 °F to +200 °F (typical elastomer range)

Details

Dynamic Seal 302951 High Quality WaterJet Cutting Machines Parts

Specifications

Manufacturer / OEM Part: 302951

Outer Diameter (OD): 0.570 in (14.48 mm)

Inner Diameter (ID): 0.311 in (7.90 mm)

Cross-Section: Standard dynamic seal profile

Material: Gray elastomer (proprietary blend for high-pressure wear resistance)

Pressure Rating: Up to 60 000 psi (4 100 bar)

Operating Temperature: −20 °F to +200 °F (typical elastomer range)

Installation & Maintenance

Depressurize System: Safely relieve pump pressure and drain fluid before disassembly.

Disassemble Piston Assembly: Remove the cylinder head and extract the piston per OEM service manual.

Remove Old Seal: Pry out the worn dynamic seal using a non-marring pick.

Inspect Components: Clean and inspect piston and bore for scoring; polish minor imperfections.

Install New Seal: Lubricate seal lip with pump oil, press into gland groove ensuring flush seating.

Reassemble & Test: Reinstall piston, cylinder head, repressurize slowly, and verify stable pressure under no-load conditions.

Product recommendation

Sapphire Long Stem 0.18 mm Orifice Assembly 20431118 Waterjet Parts In Stock

Waterjet Coil 307137 Axis 2 ABB IRB 1600 With Good Quality Robotic Waterjet Parts For Sale

Reduction Gear 3HAC031958-001 For Robot Water Jet Cutting Machine Parts In Stock

Waterjet Pump Plunger SP-46-3 Waterjet Parts In Stock

3D Laser Engraving Machine 100W Laser Cutter Cutting Machine

Small Waterjet Machine 3D Water Jet Cutting Machine Company

HP Seal Kit CP022100/220 For Waterjet Pump Parts 1-18293