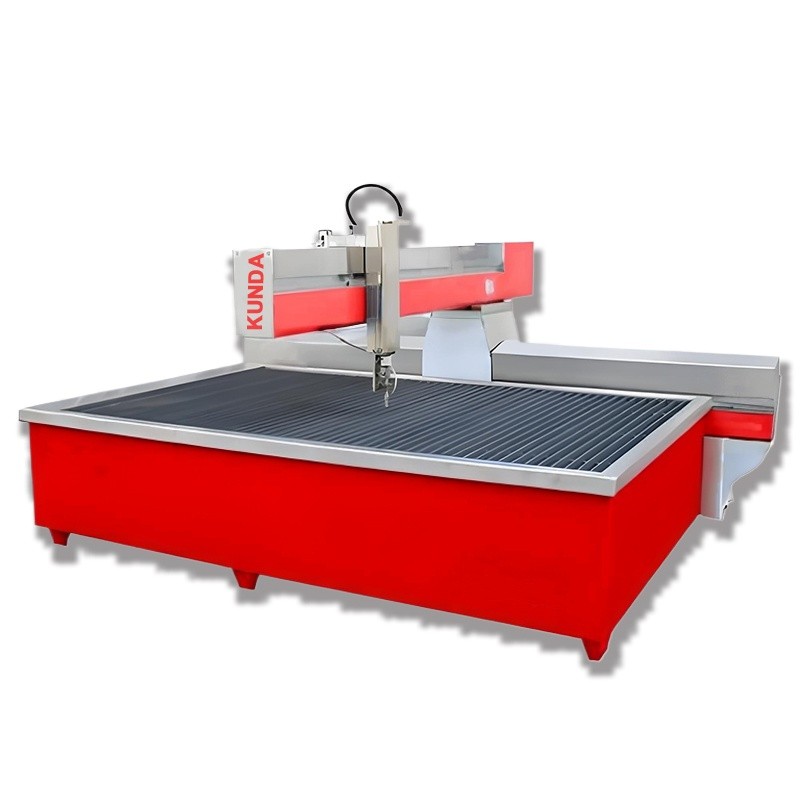

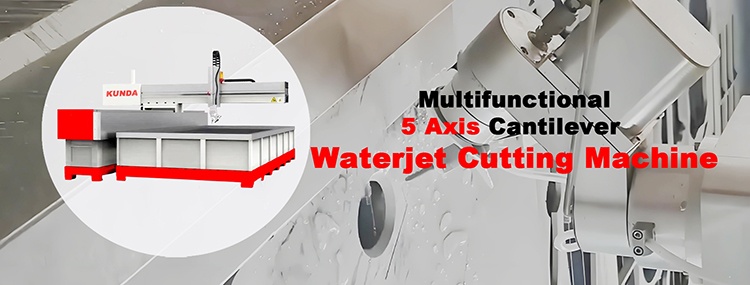

90 000 Psi Water Jet Lifting 5Axis Mini Waterjet Cutter Cantilever Cutting Machine

90 000 Psi Water Jet Lifting 5Axis Mini Waterjet Cutter Cantilever Cutting Machine

90 000 Psi Water Jet refers to a high-pressure water jet cutting technology that uses a cantilever mechanical structure and combines abrasives. This equipment combines the kinetic energy of high-pressure water jets and the grinding effect of abrasives, and can efficiently cut a variety of hard materials (such as metals, stones, composite materials, etc.).

Model

KD1015

KD2015

KD3015

KD3020

KD4018

Structure

Cantilever

Cutting Table Size

1200*1700mm

2200*1700mm

3200*1700mm

3200*2200mm

4200*2000mm

Stroke

X axis

1000mm

2000mm

3000mm

3000mm

4000mm

Y axis

1500mm

1500mm

1500mm

2000mm

1800mm

Z axis

130mm

130mm

130mm

130mm

130mm

Accuracy

Cutting

±0.1mm

Repeatability

±0.05mm

Traverse Speed

6000-15000mm/min

Power Supply

220v/380v/415v,50/60Hz

1. Basic principles 90 000 Psi Water Jet

Material

Thickness

Orifice

320Mpa

380Mpa

420Mpa

Aluminum

6mm

0.33mm

400-520mm/min

460-590mm/min

500-580mm/min

13mm

300-380mm/min

350-420mm/min

400-510mm/min

19mm

220-280mm/min

260-380mm/min

300-420mm/min

Stainless STeel

6mm

200-260mm/min

240-310mm/min

260-350mm/min

13mm

80-120mm/min

100-150mm/min

125-180mm/min

20mm

50-65mm/min

70-90mm/min

100-120mm/min

30mm

15-25mm/min

30-40mm/min

40-50mm/min

Glass

6mm

1200-1400mm/min

1600-1900mm/min

2100-2300mm/min

10mm

600-700mm/min

700-800mm/min

820-900mm/min

20mm

330-400mm/min

400-500mm/min

600-800mm/min

Marble

10mm

1000-1200mm/min

1200-1400mm/min

1350-1550mm/min

20mm

400-500mm/min

600-700mm/min

750-850mm/min

30mm

220-300mm/min

310-380mm/min

400-480mm/min

50mm

70-90mm/min

100-120mm/min

130-150mm/min

Ceramic Tile

15mm

1200-1400mm/min

1400-1500mm/min

1600-1800mm/min

Bronze

5mm

500-600mm/min

700-800mm/min

900-1000mm/min

15mm

190-220mm/min

220-300mm/min

330-400mm/min

30mm

80-100mm/min

100-120mm/min

120-150mm/min

High-pressure water jet: water is pressurized by an ultra-high pressure (usually the pressure can reach 300-600 MPa) to form a high-speed jet.

Abrasive addition: abrasives (such as pomegranate sand, aluminum oxide, etc.) are mixed in the high-pressure water flow to form a water-sand mixed jet to enhance cutting ability.

Cantilever structure: The equipment adopts a cantilever mechanical design, and the cantilever can move flexibly, which is suitable for cutting large-sized workpieces or complex shapes.

2. Equipment composition 90 000 Psi Water Jet

Cantilever system: provides lateral and longitudinal freedom of movement, usually controlled by a numerical control system (CNC) to achieve high-precision cutting paths.

High-pressure Pump: core component, providing ultra-high pressure power for water jets.

Abrasive supply system: store and precisely control the mixing ratio of abrasives.

Cutting head: integrated nozzle (gem nozzle or diamond nozzle), adjust the water-sand mixed jet.

Control system: control cutting path, speed and pressure through programming or software.

3. Technical advantages 90 000 Psi Water Jet

Wide applicability: can cut metal (steel, titanium alloy), stone, glass, ceramic, composite materials, etc.

Cold cutting: no heat affected zone, avoiding material deformation or performance change.

High precision: CNC system supports complex contour cutting with a tolerance of up to ±0.1mm.

Environmental protection and energy saving: no harmful gas or dust (water circulation system is required).

Flexibility: cantilever structure is suitable for large workpieces or small space operations.