News

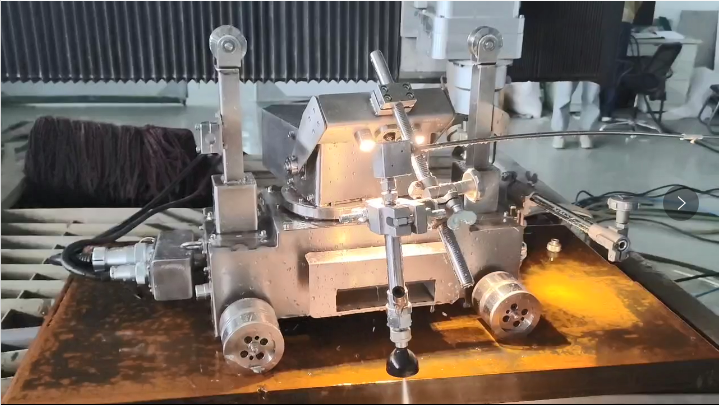

High-Pressure Waterjet Cutting Machine Shipped to Indonesian Stone Factory

Brief Introduction to High-Pressure WaterJet Cutting Machines:

A high-pressure waterjet cutting machine, also known as a WaterJet Cutter, utilizes an ultra-high-pressure stream of water for precision cutting. Water is pressurized to extreme levels (typically 380–600 MPa) and expelled through a specialized nozzle at speeds exceeding Mach 3. This generates a focused cutting stream capable of processing diverse materials—including metals, stone, glass, ceramics, plastics, and composites—with exceptional precision, zero thermal distortion, and smooth edges.

Advantages of Waterjet Cutting Technology:

Compared to traditional mechanical methods, waterjet cutting offers:

Cost Efficiency: Lower operational expenses and simplified processes.

Superior Cutting Quality: Clean edges without burrs or micro-cracks.

Eco-Friendliness: No secondary pollution or hazardous byproducts.

Enhanced Safety: Non-thermal process eliminates fire/explosion risks (e.g., safely separates explosives from shells).

Automation Compatibility: Ideal for green, automated industrial workflows.

Prospects in Indonesia’s Stone Industry:

Indonesia’s accelerating urbanization, infrastructure development, and booming commercial/residential projects drive robust demand for stone products—particularly internationally sought-after marble and granite. Waterjet cutting machines are pivotal in meeting this demand, enabling high-precision stone processing for both domestic and export markets.

Stone & Ceramic Applications:

Stone Processing:

Cuts granite, marble, limestone, etc., for flooring, wall cladding, countertops, and artistic sculptures.

Enables intricate designs and nested cutting to maximize material yield (up to 30% waste reduction).

Ceramic Processing:

Precision-cuts tiles, panels, and art pieces for architectural and decorative use.

Cold Cutting Technology:

Operates at temperatures <40°C, preventing thermal stress or structural changes in materials.

Complex Shape Cutting:

Achieves tight tolerances (±0.1mm) for custom geometries without tooling costs.

Industry Adoption:

High-pressure waterjet systems are extensively deployed across Indonesia’s stone and ceramic sectors, revolutionizing production efficiency and design capabilities.