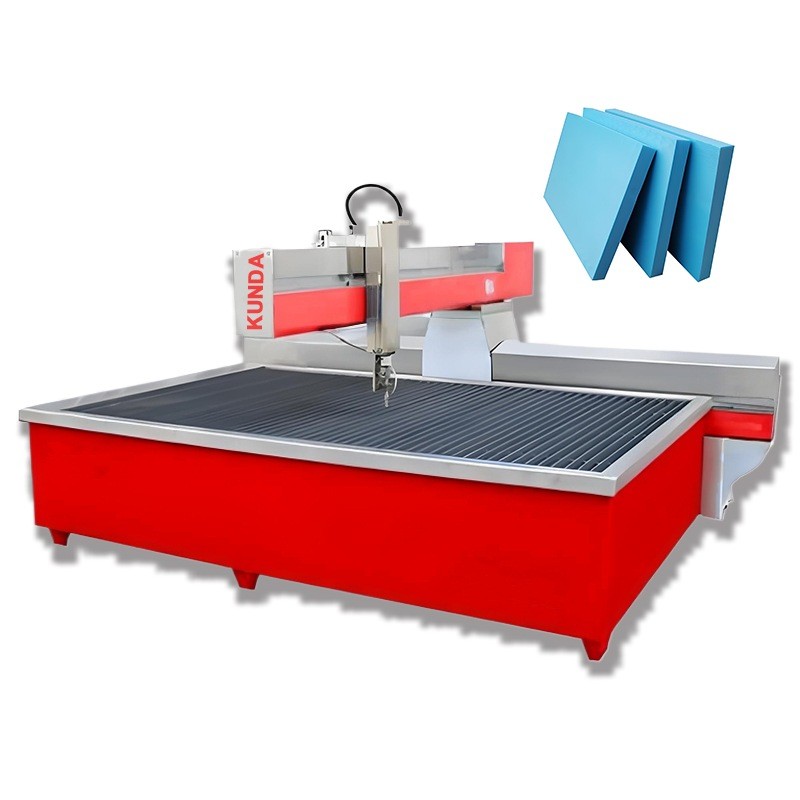

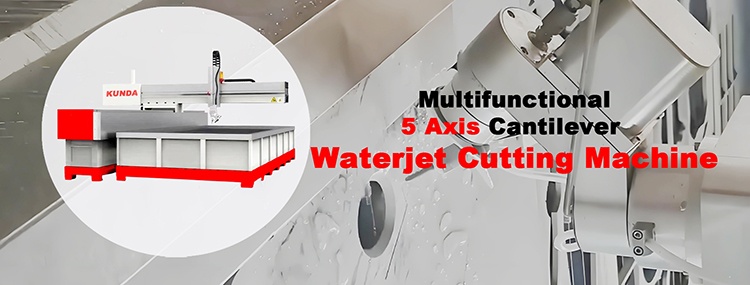

Best Water Jet Machine Cantilever Small Waterjet High Pressure Cutting Machine Price

Best Water Jet Machine Cantilever Small Waterjet High Pressure Cutting Machine Price

Best Water Jet Machine is a cutting technology that combines high-pressure water jets with abrasive particles. It enhances cutting ability by mixing abrasives such as garnet sand. It is suitable for precision machining of hard materials such as metals and composite materials.

| Model | KD1015 | KD2015 | KD3015 | KD3020 | KD4018 | |

| Structure |

Cantilever |

|||||

|

Cutting Table Size |

1200*1700mm | 2200*1700mm | 3200*1700mm | 3200*2200mm | 4200*2000mm | |

| Stroke | X axis | 1000mm | 2000mm | 3000mm | 3000mm | 4000mm |

| Y axis | 1500mm | 1500mm | 1500mm | 2000mm | 1800mm | |

| Z axis | 130mm | 130mm | 130mm | 130mm | 130mm | |

|

Accuracy |

Cutting |

±0.1mm |

||||

| Repeatability |

±0.05mm |

|||||

| Traverse Speed |

6000-15000mm/min |

|||||

|

Power Supply |

220v/380v/415v,50/60Hz | |||||

| Material | Thickness | Orifice | 320Mpa | 380Mpa | 420Mpa |

|

Aluminum |

6mm |

0.33mm |

400-520mm/min | 460-590mm/min | 500-580mm/min |

| 13mm | 300-380mm/min | 350-420mm/min | 400-510mm/min | ||

| 19mm | 220-280mm/min | 260-380mm/min | 300-420mm/min | ||

|

Stainless STeel |

6mm | 200-260mm/min | 240-310mm/min | 260-350mm/min | |

| 13mm | 80-120mm/min | 100-150mm/min | 125-180mm/min | ||

| 20mm | 50-65mm/min | 70-90mm/min | 100-120mm/min | ||

| 30mm | 15-25mm/min | 30-40mm/min | 40-50mm/min | ||

|

Glass |

6mm | 1200-1400mm/min | 1600-1900mm/min | 2100-2300mm/min | |

| 10mm | 600-700mm/min | 700-800mm/min | 820-900mm/min | ||

| 20mm | 330-400mm/min | 400-500mm/min | 600-800mm/min | ||

|

Marble |

10mm | 1000-1200mm/min | 1200-1400mm/min | 1350-1550mm/min | |

| 20mm | 400-500mm/min | 600-700mm/min | 750-850mm/min | ||

| 30mm | 220-300mm/min | 310-380mm/min | 400-480mm/min | ||

| 50mm | 70-90mm/min | 100-120mm/min | 130-150mm/min | ||

| Ceramic Tile | 15mm | 1200-1400mm/min | 1400-1500mm/min | 1600-1800mm/min | |

|

Bronze |

5mm | 500-600mm/min | 700-800mm/min | 900-1000mm/min | |

| 15mm | 190-220mm/min | 220-300mm/min | 330-400mm/min | ||

| 30mm | 80-100mm/min | 100-120mm/min | 120-150mm/min |

High-pressure water jet: water is pressurized by an ultra-high pressure (usually the pressure can reach 300-600 MPa) to form a high-speed jet.

Abrasive addition: abrasives (such as pomegranate sand, aluminum oxide, etc.) are mixed in the high-pressure water flow to form a water-sand mixed jet to enhance cutting ability.

Cantilever structure: The equipment adopts a cantilever mechanical design, and the cantilever can move flexibly, which is suitable for cutting large-sized workpieces or complex shapes.

2. Equipment composition Best Water Jet Machine

Cantilever system: provides lateral and longitudinal freedom of movement, usually controlled by a numerical control system (CNC) to achieve high-precision cutting paths.

High-pressure Pump: core component, providing ultra-high pressure power for water jets.

Abrasive supply system: store and precisely control the mixing ratio of abrasives.

Cutting head: integrated nozzle (gem nozzle or diamond nozzle), adjust the water-sand mixed jet.

Control system: control cutting path, speed and pressure through programming or software.

3. Technical advantages Best Water Jet Machine

Wide applicability: can cut metal (steel, titanium alloy), stone, glass, ceramic, composite materials, etc.

Cold cutting: no heat affected zone, avoiding material deformation or performance change.

High precision: CNC system supports complex contour cutting with a tolerance of up to ±0.1mm.

Environmental protection and energy saving: no harmful gas or dust (water circulation system is required).

Flexibility: cantilever structure is suitable for large workpieces or small space operations.

More details,please contact us!

INQUIRY