Metal Engraving Machine Aluminum Laser Cutter Engraving Machine For Metal

Metal Engraving Machine Aluminum Laser Cutter Engraving Machine For Metal

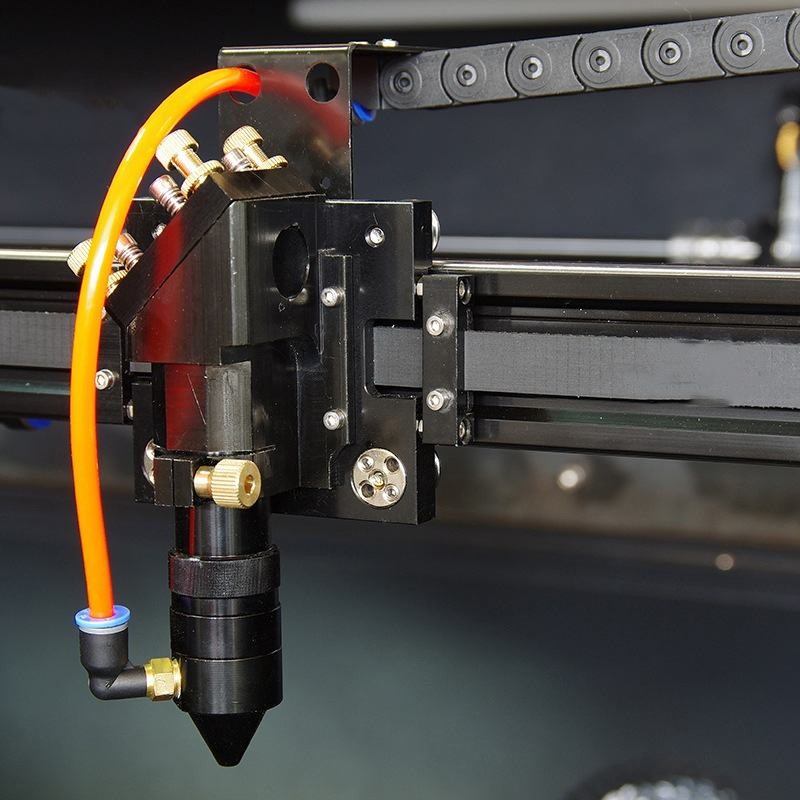

Metal Engraving Machine is a CNC device that uses high-energy laser beams to perform fine processing on the surface of materials. Its basic principle is to focus the beam emitted by the laser onto the surface of the workpiece, instantly causing the material in the irradiated area to evaporate or ablate at high temperature, thereby forming visible dents or marks. Laser processing uses digital control and can be divided into two modes: dot matrix (progressive scanning) engraving and contour (vector) cutting, to achieve precise processing of text and patterns. Compared with traditional mechanical processing, laser engraving has the advantages of non-contact, high precision, and wide application of materials.

|

Laser power |

60W/80W/100W/130W/150W |

|

Working voltage |

customizable |

|

Working platform |

aluminum knife platform, honeycomb platform |

|

Working area |

900*6OOMM |

|

Engraving speed |

100OMM/S |

|

Cutting speed |

5OOMM/S |

|

Engraving size |

90O*6OOMM |

|

Cutting thickness |

20MM (depending on the material) |

|

Control mode |

CNC |

|

System environment |

0-40 degrees Celsius |

|

Cooling method |

water cooling |

|

Supported formats |

all vector graphics, bitmaps |

|

Water temperature requirement |

0-40 degrees Celsius |

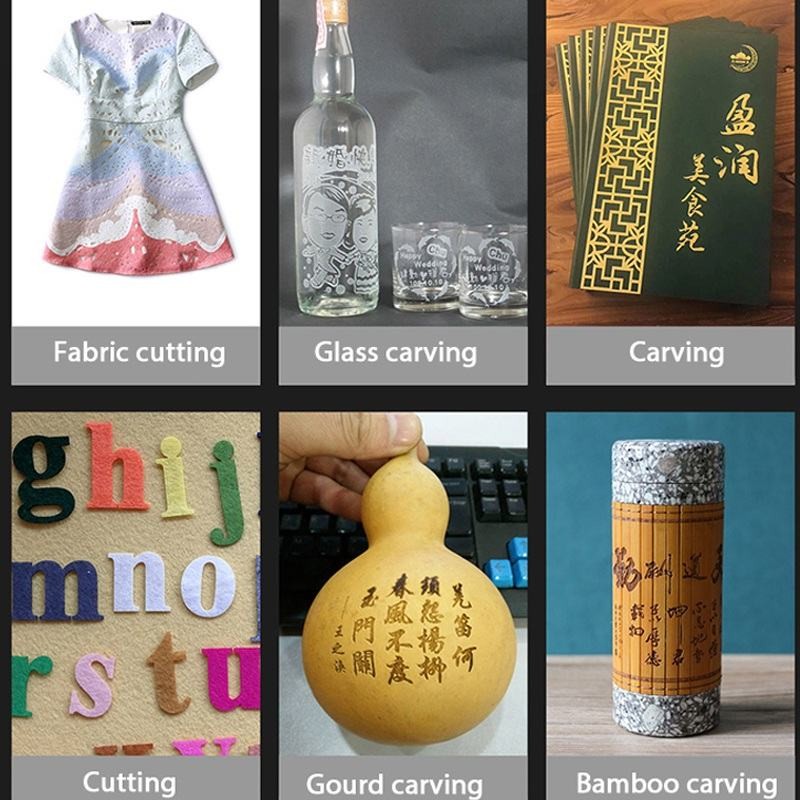

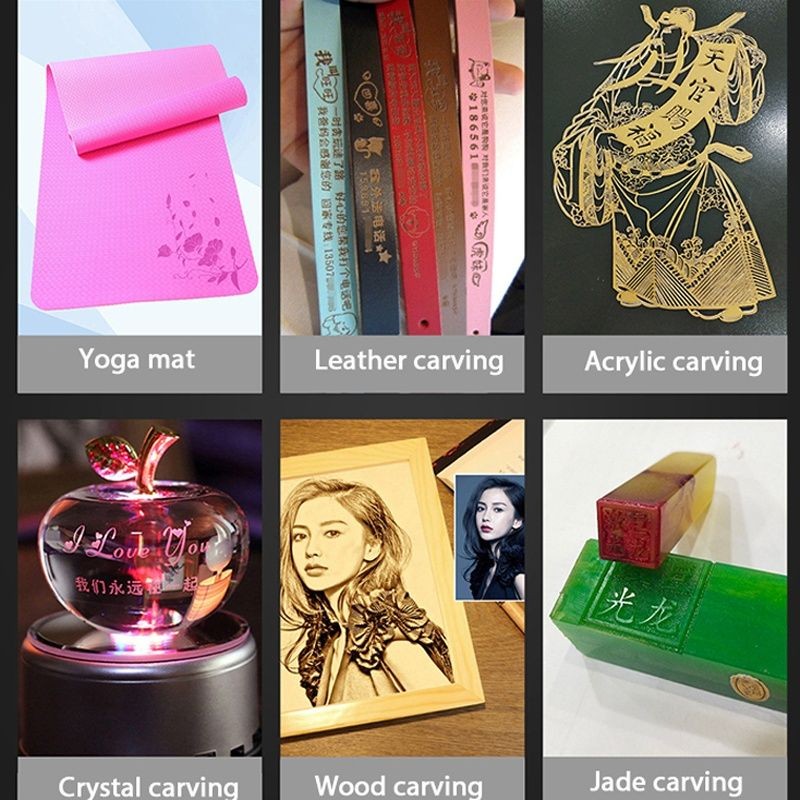

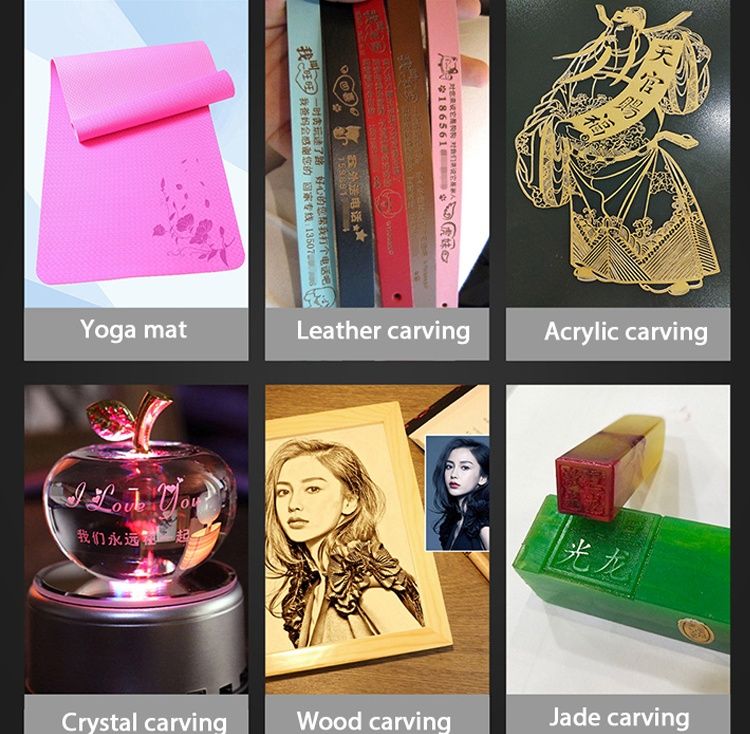

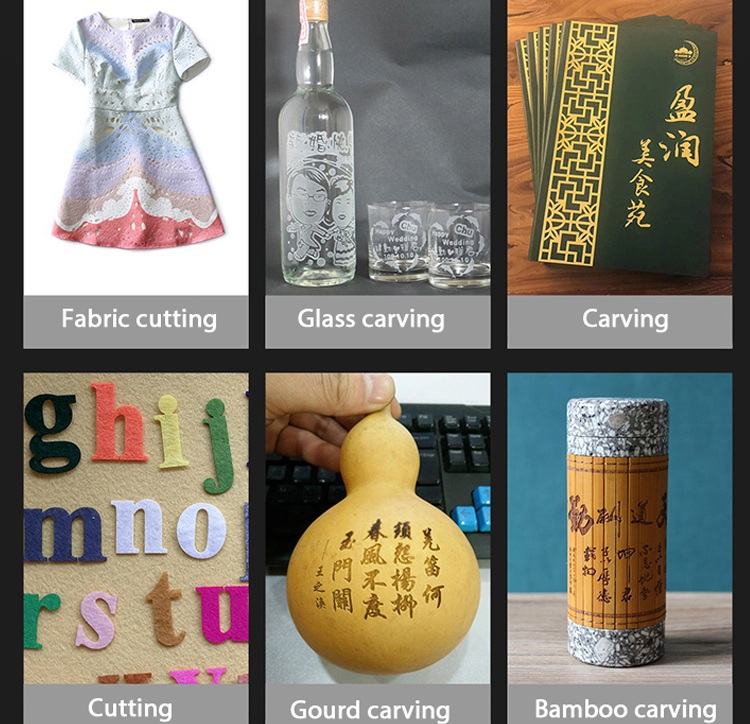

Plastics and resins: Metal Engraving Machine are often used to cut plastic sheets and engrave patterns; fiber lasers can mark on certain plastic surfaces; UV lasers are suitable for plastics and films that are easily deformed.

Wood and paper: When laser cutting wood, the cutting surface is smooth, leaving only a thin carbonized layer; engraving can finely depict the texture.

Glass and ceramics: Etching patterns on the surface of glassware or etching logos on ceramics and tiles.

Leather and textiles: Metal Engraving Machine are easy to process leather and fabrics, and can cut leather patterns and engrave patterns; fiber lasers are also effective for some leather materials.

Other materials: Stone (marble, granite, etc.), synthetic panels (stone-plastic panels, composite panels), paper, rubber, etc., can all choose the appropriate laser type for engraving or cutting according to needs.

Typical application scenarios

Advertising production industry: Use Metal Engraving Machine to cut and engrave acrylic, plexiglass and colored plates to produce three-dimensional characters, company logos, display boards and signboards, etc.

Industrial manufacturing field: Laser engraving the vehicle identification number (VIN) and serial number on the engine block, chassis or frame of the car can achieve high-precision anti-tampering marking to meet the traceability management needs.

In addition, Metal Engraving Machine are also used for mold processing and tooling surface engraving, which is fast, has no knife marks, and is easy to achieve complex patterns.

Electronic products industry: Metal Engraving Machine plays an important role in the manufacture of electronic components and complete machines. On the one hand, the manufacturer's logo, model and port label can be marked on the printed circuit board (PCB) to ensure accuracy during assembly and debugging; on the other hand, the plastic or metal shell of electronic equipment such as notebooks and mobile phones can also be laser engraved to achieve personalized customization and brand identification.

Medical device industry: The medical field has extremely high requirements for marking accuracy and durability.Metal Engraving Machine can engrave important information such as serial numbers, barcodes, models, etc. on surgical instruments, scalpels, etc., ensuring that each instrument can be traced and correctly identified.

Craft gifts and jewelry: engrave words and patterns on medals, trophies, and customized gift boxes, as well as engrave personalized text or patterns on gold and silver jewelry (rings, necklaces), wooden crafts, leather accessories, etc.