Waterjet Cutting Pump Waterjet Glass Cutting Machine With Good Price

Waterjet Cutting Pump Waterjet Glass Cutting Machine With Good Price

|

Nominal Power Rate |

40hp (30 kW) |

Control Voltage & Power Supply |

24V DC; 5 Amps DC |

|

Max. Continuous Pressure |

Max. Continuous Pressure |

Max. Noise Level |

75 dB (A) |

|

Max. Water Flow Rate |

1.0 gpm (3.8 L/min) |

Ambient Operating Temperature |

Min. 40ºF (5º C), Max. 104ºF(40º C) |

|

Max. Single Orifice Dia. |

.014 in. (0.36 mm) |

Hydraulic Reservoir Capacity |

114 L |

|

Length |

1600mm |

Attenuator Volume |

1L |

|

Width |

1200mm |

Weight |

0.9t |

|

Height |

1100mm |

|

The Waterjet Cutting Pump for Water Jet cutting is the core component of modern high-pressure water jet cutting systems and is widely used for precision cutting in industries such as metal, stone, glass, and composite materials. Its main function is to boost the low-pressure water source to a high pressure of 60,000 to 90,000 psi (about 4,100 to 6,200 bar) through the hydraulic booster principle to drive the Water Jet Cutting Head for efficient cutting.

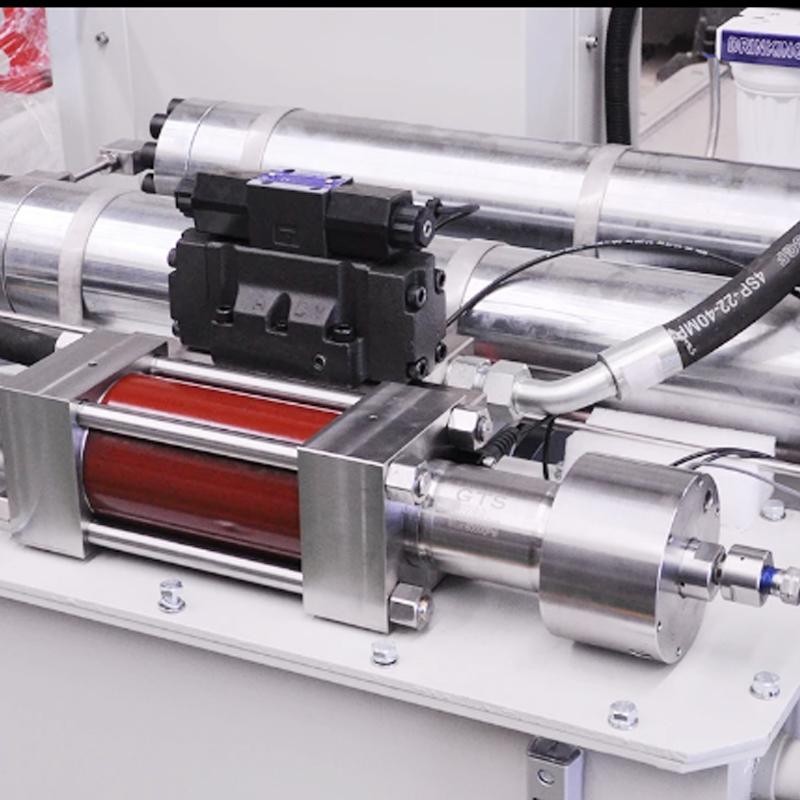

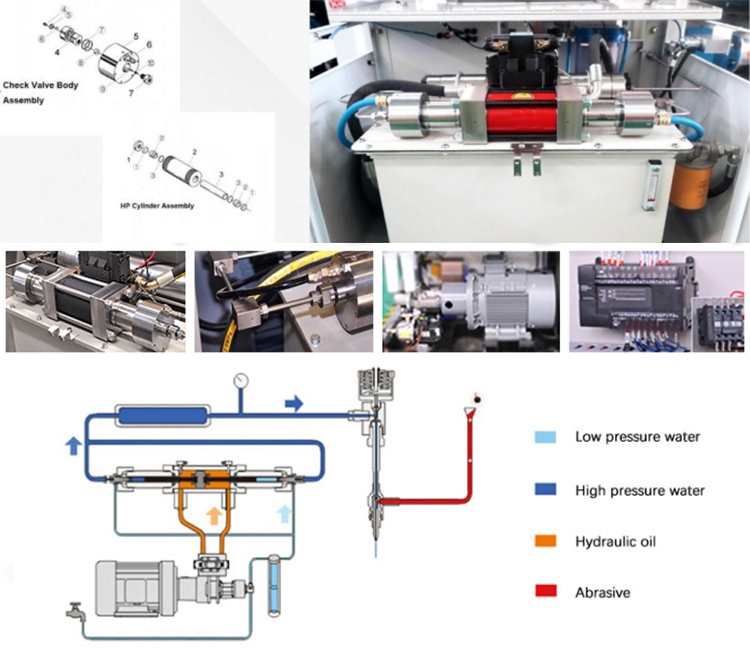

The Waterjet Cutting Pump uses the oil pressure in the hydraulic system to push the piston, which is connected to the plunger. The low-pressure oil pressure is converted into high-pressure water flow through the ratio of the piston area to the plunger area. This boosting principle is similar to the working mechanism of a hydraulic press, that is, the oil pressure multiplied by the piston area is equal to the water pressure multiplied by the plunger area.

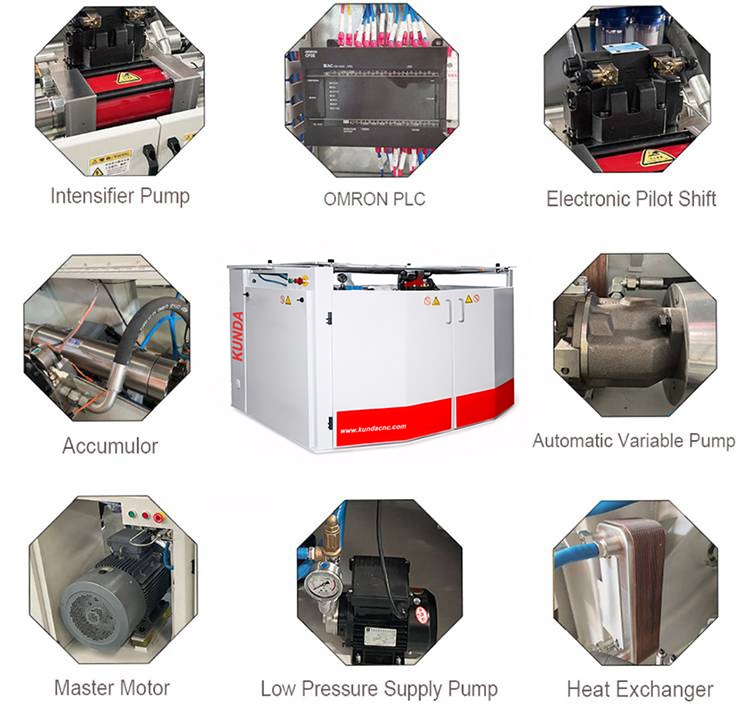

Main components Waterjet Cutting Pump

Hydraulic system: Provides power to push the booster to perform piston movement.Booster assembly: The core component, which generates high-pressure water flow by hydraulically driving the plunger.

Accumulator: Stores hydraulic energy to ensure the continuous operation of the booster.

Control system: Regulates and monitors the working status of the pump to ensure stable operation of the Waterjet Cutting Pump.