News

How does water jet pumps work?

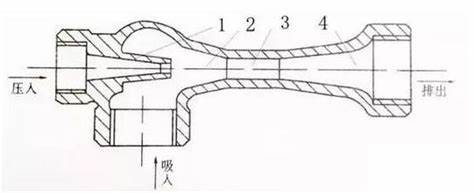

The waterJet Pump is usually used in the water jet cutting system, and its working principle is the hydraulic amplification principle. This process involves connection through a hydraulic system. So, how does this Waterjet Pump work? Now, let our Kunda's professional technical engineers introduce it to you:What is a waterjet pump and how does it work?

So, what should customers pay attention to when purchasing a waterjet pump?

The price of our waterjet pumps varies depending on the different models of Water Jet Machines. Generally speaking, there are still the following points to note:1.cylinder ----- with piston inside, cylinder end cover at both ends, pulled by the pull rod, hydraulic oil enters the cylinder through the oil hole of the cylinder end cover, causing the piston to move back and forth inside the cylinder.

2. Piston - The piston is connected to the piston rod on both sides and fixed by a gland. It is installed inside the cylinder and moves back and forth within it. The working power of the piston comes from the push and pull of the hydraulic oil inside the cylinder.

3. Oil circuit plate of waterjet pump - The oil circuit plate is installed on the oil hole surface of the cylinder end cover. On the other side, the electromagnetic directional control valve is installed. The oil pipe opening is connected to the oil pump through an oil pipe.

4. Electromagnetic directional control valve - The electromagnetic directional control valve is a component that controls the direction of the hydraulic oil flowing in and out of the cylinder through the oil circuit plate. It plays a crucial role in controlling the left and right reciprocating motion of the piston, which is essential for the pressure increase of the booster pump.

5. High-pressure maintenance assembly - It consists of 4 pieces of high-pressure rings, O-rings, and alloy rings. It is installed inside the high-pressure cylinder body, with the inner ring surrounding the piston rod, providing a high-pressure water seal.

6. Low-pressure oil seal assembly - It is a set of installation kits composed of multiple sealing rings, installed at multiple oil holes of the cylinder end cover and contact surfaces of various parts to ensure that the hydraulic oil does not leak out.

7. Cylinder end cover - The cylinder end cover is installed at both ends of the cylinder through four sets of tie rods. Low-pressure sealing rings are installed at each oil hole, and the oil circuit plate is installed at the oil inlet and outlet holes. The piston rod passes through the central hole.

8. Directional change sensing assembly - It is composed of a directional change push rod, a directional change spring, a sensor, etc. It is installed from the external entrance into the directional change execution hole of the cylinder end cover and fixed by a fixed seat.

9. Oil cylinder end cover pull rod - The pull rod is inserted into the round holes at the corners of the oil cylinder end covers on both sides, and then the nuts on both sides are tightened to pull the oil cylinder end covers tightly together, ensuring a stable and firm connection with the oil cylinder.

10. Piston rod - The larger diameter end is inserted into the groove of the piston. After the cover is installed, a retaining ring is inserted into the inner groove of the piston to ensure a stable installation. It moves within the high-pressure cylinder and comes into contact with the high-pressure seal, requiring a high degree of surface finish.

12. High-pressure cylinder body - The high-pressure cylinder body is the source of high-pressure water. The higher the pressure generated, the higher the pressure it must withstand, and the higher the material requirements for the high-pressure cylinder body. It is installed on the outer side of the oil cylinder end cover.

13. High-pressure cylinder liner - The high-pressure cylinder liner is installed in the high-pressure cylinder body before the high-pressure seal assembly. It serves to stabilize the high-pressure seal assemblies on both sides and prevent them from moving.

How to maintain a waterjet pump after purchasing it?

1. When connecting the high-pressure pipe, to prevent water leakage from the high-pressure pipe, the threaded end of the high-pressure pipe should be higher than the three teeth of the gasket.2. It is recommended to loosen the threaded connection between the high-pressure cylinder and the low-pressure cylinder cover every two or three days to prevent the connection from being too tight. Water jet cutting machines have excellent flexibility and can cut any shape of workpiece at any time. Especially when the material is thick and hard, the punching and shearing process will be very difficult or impossible to achieve, while the waterjet cutting method is relatively ideal.

3.After becoming proficient in operating and controlling the water jet, appropriate pressure should be used to divide the object. This not only increases work efficiency but also significantly extends the service life of the accessories.

4.If there is any fault that the operator is unsure about, do not disassemble and repair it without authorization. Feedback should be given to a professional water jet cutting machine manufacturer, such as Kunda, which has professional maintenance engineers to analyze the fault and then guide the repair.

Thank you all for your reading. That's all for the knowledge points about Water Jet Pump. If you have any questions, please feel free to call us at any time for communication