Jet Pump Jet Pump Wholesale Direct Drive Waterjet Pressure Pump Exporter

Jet Pump Jet Pump Wholesale Direct Drive WaterJet Pressure Pump Exporter

As the core power source of a WaterJet Cutting Machine, a Jet Pump Jet Pump boosts water pressure to 40,000–90,000 psi or even higher, creating an extremely high-speed, high-pressure water jet. This powerful water stream effortlessly cuts through metal, stone, glass, plastic, and various composite materials.

The Jet Pump Jet Pump's high-pressure plunger design ensures stable water flow, allowing the nozzle to eject an ultra-fine, powerful jet of water, ensuring precise and efficient cutting. Whether used in industrial manufacturing or precision machining, Waterjet Pumps demonstrate exceptional reliability and durability, providing businesses with continuous, powerful power support.

Rated Power

37KW/40HP

Max. operating pressure

480MPa/69000psi

Continuous working pressure

380MPa-420MPa

Max. discharging rate

4.2L/min

Orifice diameter

0.33mm or others

Nozzle diameter

1.02mm or others

Tank volume

150L

Size

1800mm*1100mm*1300mm

Weight

900KG

Ambient Operating Temperature

Min.40°F(5° C), Max. 1049F(40°C)

Max. Noise Level

75 dB (A)

Attenuator Volume

1L/2L

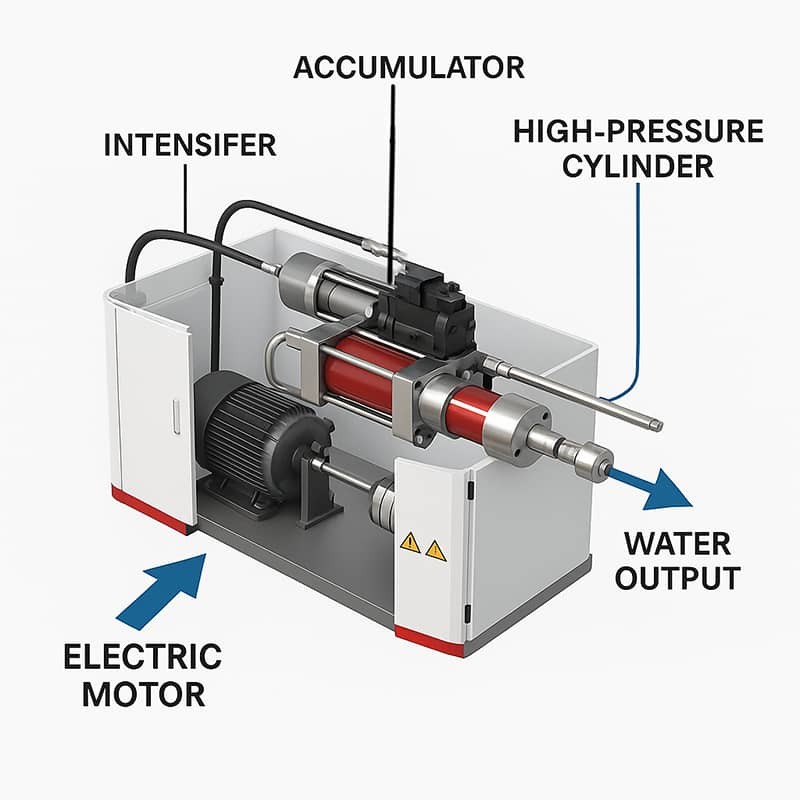

Working Principle of a Jet Pump Jet Pump

A waterjet pump (also known as a booster) boosts ordinary low-pressure water to extremely high pressure, creating A Water Jet for cutting. Its core principle is to use hydraulic or water pressure to drive a high-pressure plunger, continuously compressing and increasing the pressure of the water.In this process, the ratio between the hydraulic oil pressure and the water pressure is called the "intensification ratio." By adjusting this ratio, the water pressure can be precisely controlled. According to the principle of conservation of energy, under ideal conditions, the product of the oil pressure and the piston cross-sectional area is equal to the product of the water pressure and the high-pressure plunger cross-sectional area. This is the basis for the pump's efficient pressure intensification.

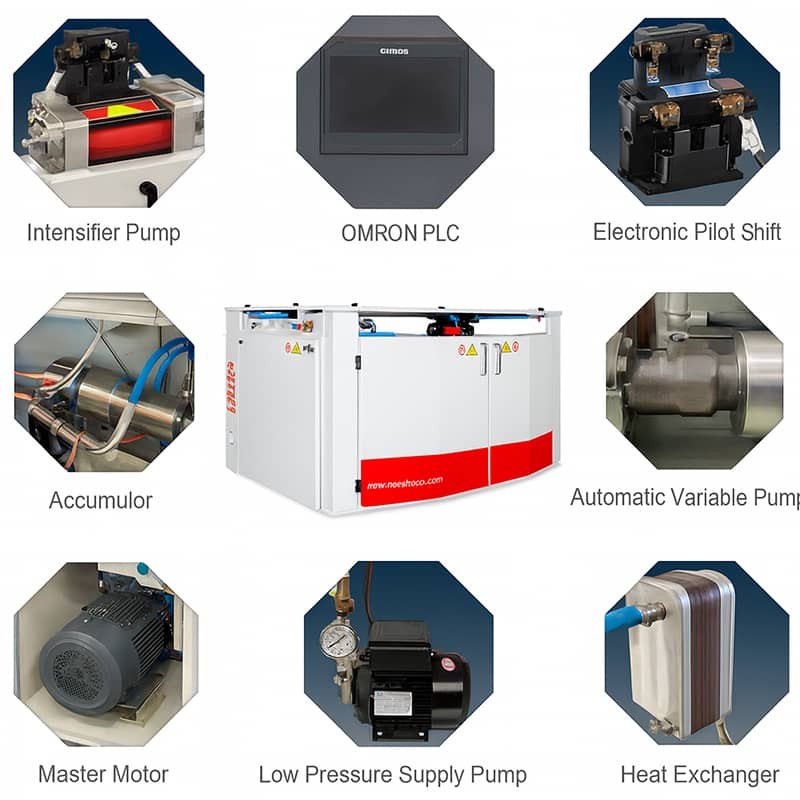

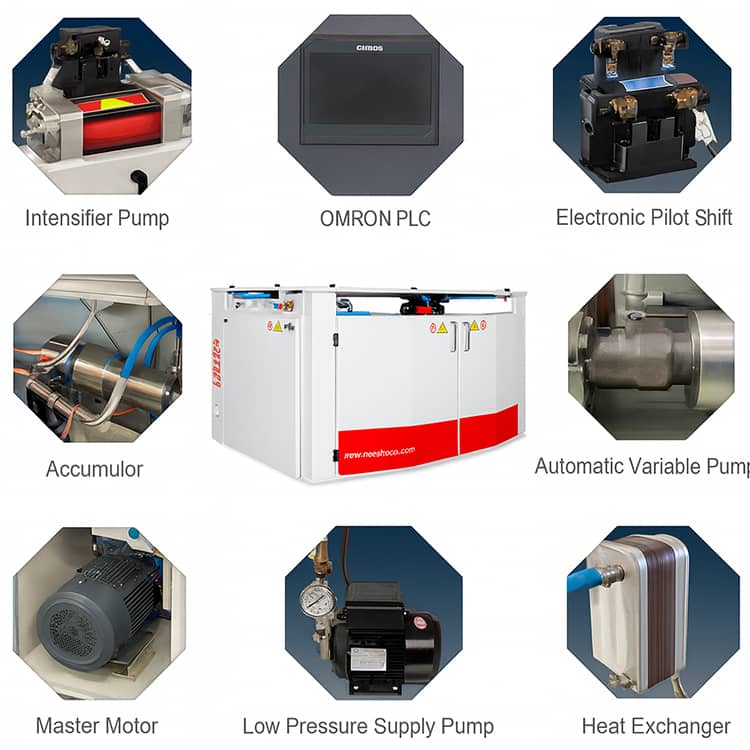

Components of a Jet Pump Jet Pump

A waterjet pump is one of the core components of a waterjet cutting machine. Its supporting system includes:Waterjet Cutting Head: forms and directs the high-pressure water jet.

CNC machining platform: controls the cutting path and processed shape according to a program.

Abrasive supply system: provides abrasive in abrasive waterjet applications, enhancing cutting performance.

Advantages of Jet Pump Jet Pump

Cold Cutting: No heat is generated during the cutting process, preventing thermal deformation or heat-affected zones (HAZs) in the material, making it particularly suitable for heat-sensitive materials.High Precision: Capable of cutting complex shapes and high precision.

Environmentally Friendly: No harmful gases are generated during the cutting process, making it safer and more environmentally friendly.

Versatile: Suitable for a wide range of materials, from foam and glass to steel and titanium alloys.