Industry-news

How Much Do You Know About Waterjet Intensifier Pumps?

How Much Do You Know About Waterjet Intensifier Pumps?

Next, I will discuss the core value of 60000 Psi Waterjet Pump from the aspects of principle, structure, application, and selection.

1. What is a Energy Efficient WaterJet Pump?

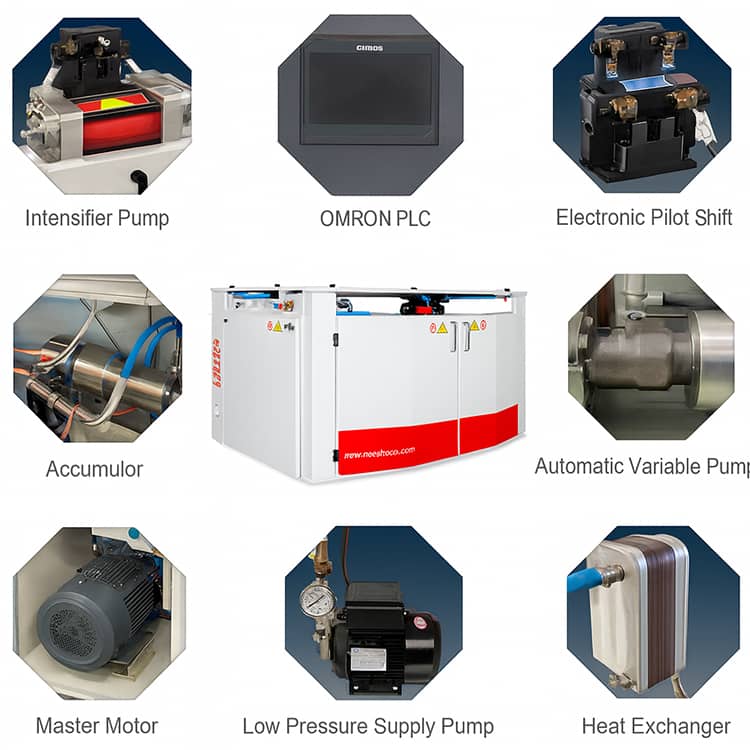

The waterjet intensifier pump is a core piece of equipment that uses hydraulic drive to increase ordinary low-pressure water to a very high pressure (generally 300–420 MPa). In a high-pressure Waterjet Cutting System, the high-pressure water is ejected from the cutting head, forming a high-speed water jet to achieve cold cutting.For example, the JET 50 waterjet intensifier pump adopts an industrial-grade design, integrating a hydraulic system, high-pressure cylinder, and control module, specifically designed for continuous, high-load waterjet cutting.

2. Working Principle of Industrial Waterjet Pump

The waterjet intensifier pump mainly involves three steps:a. Hydraulic drive: The motor drives the hydraulic pump, generating stable hydraulic oil pressure.

b. Pressure amplification (intensification): The hydraulic oil pushes a large-diameter piston, and the pressure of the small-diameter high-pressure water column increases rapidly.

c. High-pressure water output: The ultra-high-pressure water is delivered to the cutting head through high-pressure pipelines for pure water or abrasive waterjet cutting.

This process gives waterjet cutting advantages such as a small heat-affected zone, no material hardening, and smooth cuts.

3. Main Advantages of Water Jet Cutter Pump

a. Stable ultra-high-pressure output: A good intensifier pump can maintain stable pressure for a long time, ensuring consistent cutting accuracy, which is very suitable for metal and precision parts processing requiring high accuracy.b. Industrial-grade structural design: The entire machine adopts a closed cabinet structure, which is convenient for maintenance and reduces the risk of noise and oil leakage, improving the safety and cleanliness of the workshop.

c. Durable sealing system: Key sealing parts and high-pressure cylinders are made of wear-resistant materials, extending the replacement cycle of wear parts and reducing operating costs. d. Applicable to various waterjet cutting processes: It can be used for both pure water cutting (food, rubber, foam) and abrasive waterjet cutting (steel, stone, ceramics, glass, etc.).

4. Common Applications of Waterjet Cutting Pump

* Metal processing: Stainless steel, aluminum alloy, titanium alloy* Stone industry: Marble, granite, sintered stone

* Glass cutting: Architectural glass, laminated glass, bulletproof glass

* Composite materials: Carbon fiber, GFRP, honeycomb panels

* Industrial manufacturing: Aerospace, automotive parts, machinery manufacturing

5. How to Choose the Right Waterjet Pump?

* Rated pressure and flow rate: Must meet the requirements for cutting thickness and processing efficiency.* Continuous operation capability: Consider its suitability for long-term industrial production.

* Maintenance and consumable costs: The lifespan of seals and check valves should be considered.

* Brand and after-sales support: Mature technology and spare parts supply are essential.

For users who prioritize stability and cost-effectiveness, choosing a properly configured intensifier pump is more important than simply pursuing extreme pressure.

The High Pressure Intensifier Pump is not only the power source of the waterjet cutting system but also a key factor in determining cutting quality and production efficiency. Choosing a reliable, stable, and low-maintenance intensifier pump can directly improve the competitiveness of your waterjet cutting production line.

If you are looking for a high-performance waterjet intensifier pump, or would like to learn about configuration suggestions for different pressure levels and application scenarios, please feel free to contact us.