Modifiers And Intensifiers Stable Pressure Waterjet Intensifier Pump for Composite Cutting Machine

Modifiers And Intensifiers Stable Pressure Waterjet Intensifier Pump for Composite Cutting Machine

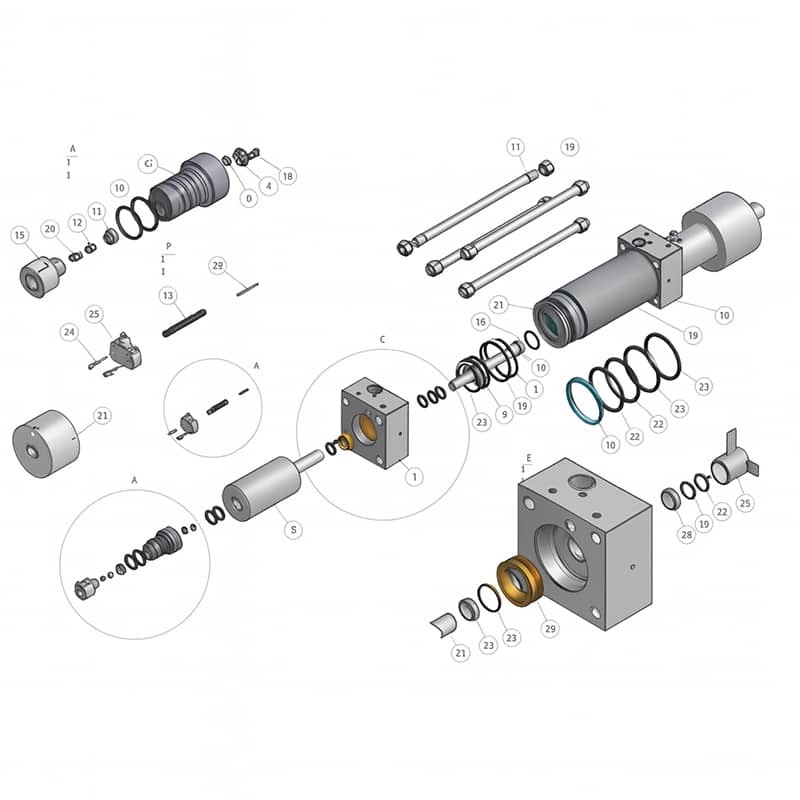

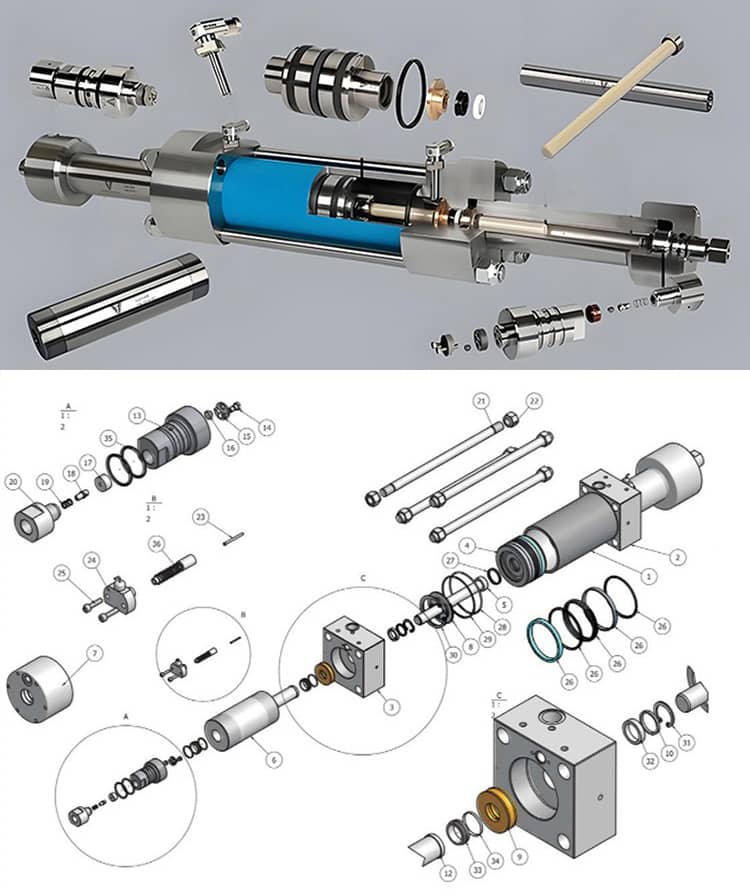

Working Principle Modifiers And Intensifiers:

High-pressure Pump Water Supply: A booster or high-pressure pump compresses the water to a pressure of 3,000–6,000 bar (approximately 40,000–90,000 psi).Accumulator Energy Storage: High-pressure water enters the accumulator, pushing the internal diaphragm/piston, storing a certain amount of energy within the accumulator.

Stable Output: When water flow demand fluctuates suddenly during the cutting process, the accumulator can quickly replenish or absorb water, preventing pressure fluctuations.

Continuous Cutting: Ensures a stable high-pressure water jet from the nozzle, resulting in higher cutting precision and smoother cuts.

Purpose and Advantages Modifiers And Intensifiers:

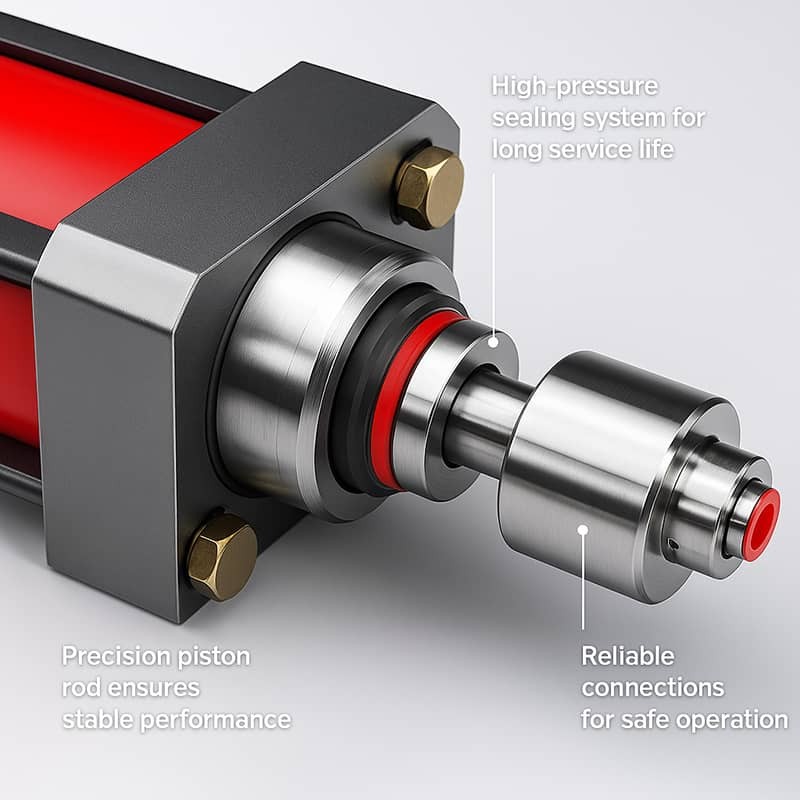

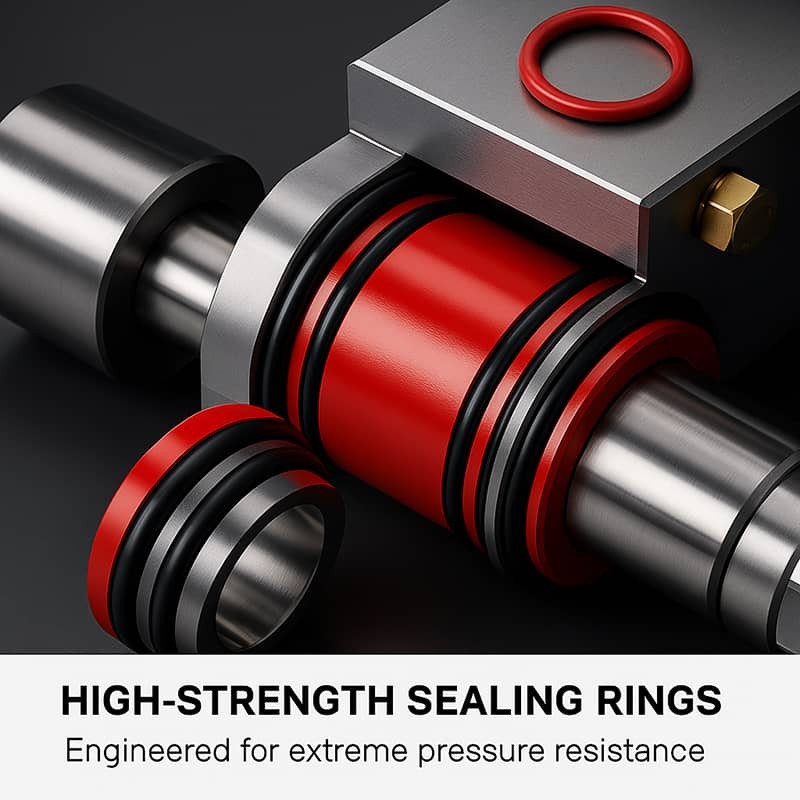

Stable Pressure: Avoids fluctuations caused by direct pump output.

Improved Cutting Quality: Ensures a continuous jet flow and smoother cuts. Extend equipment life: Reduce pressure shock in the booster and piping.

Energy savings and consumption reduction: Reduce frequent pump starts and stops, improving efficiency.

INQUIRY